WPT Vehicle Assembly

Focus on interoperability & ease of integration

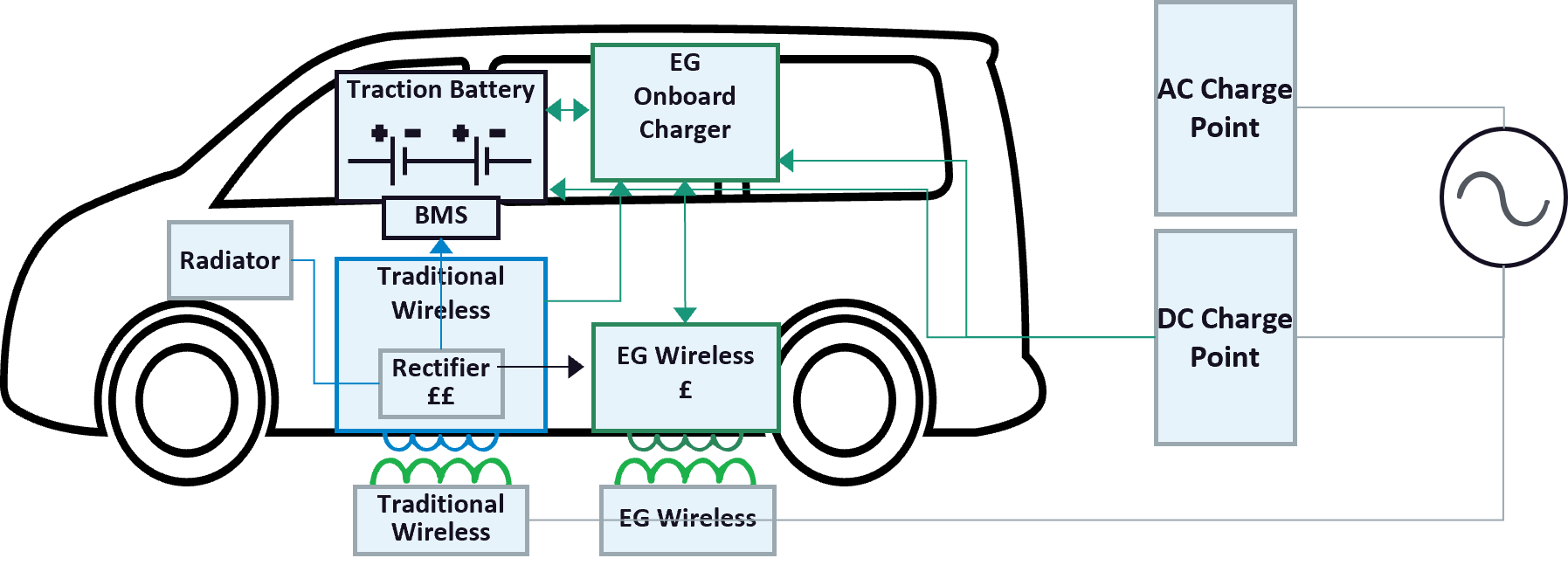

Electric Green believes that for on-vehicle wireless charging systems to be commercially successful they must be easy to integrate into vehicles as factory fitted systems. High volumes are key to reducing unit production costs, therefore components are designed to be multi-functional (can be used for plug-in AND wireless) and assist in standardising on-vehicle charging systems. This significantly reduces the duplication of power electronics, a problem which is inherent to many wireless charging solutions.

Reducing electrical complexity through intelligent design also reduces the need to manage excess heat thereby reducing the need for complex cooling system adaptations.

Our OBC (onboard charger) approach to power conversion and minimisation of VA secondary coil complexity & size are key to achieving the economies of scale which make these goals achievable.

Some of our vehicle technology is outlined below:

Reduced Duplication

Reduced Complexity

Bi-directionality

Standards Compliance

Interoperability

Our OBC (onboard charger) based system reduces duplicated power conversion steps – instead of hosting a new rectifier within the vehicle pad assembly to convert wireless AC power to DC power, we utilise the rectifier already on-board nearly all EVs.

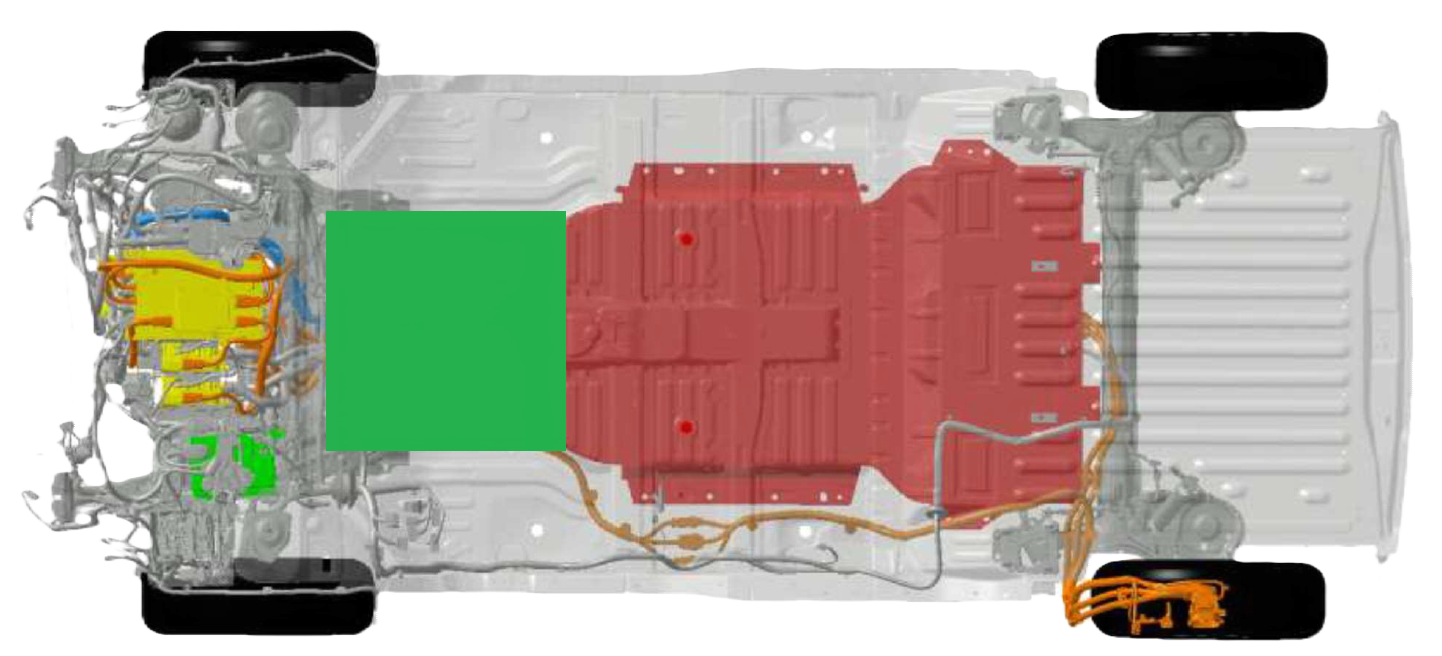

Our vehicle pad coil assembly does not require active cooling, as heat-intensive power switching is done in the centralized OBC which is plumbed for liquid cooling by default. Further, because rectification is handled by the OBC, our coil assembly can be lighter, more robust, and thinner – reducing installation costs even further.

Our solution is also bi-directional, in readiness for V2G, V2H and V2X. Communications are handled via ISO 15118-20, with a bi-directional OBC to exchange power between our bi-directional wireless charging infrastructure and the EV traction battery.

Standards compliance is key for automotive safety and interoperability. We comply with automotive & electrical standards such as ISO 26262, IEC 60950, SAE 2894/1, IEEE 1547 and SAE J2954, with communication standards like ISO 15118 and SAE J1939, just to name a few.

Interoperability is of utmost importance for the widescale adoption of wireless charging. Our vehicle assembly supports interoperability via universal high-frequency AC input (any standard wireless system), auxiliary input for hosted-rectifier wireless systems, and SAE J2954 compliant coil/pad design.

Our VA Components

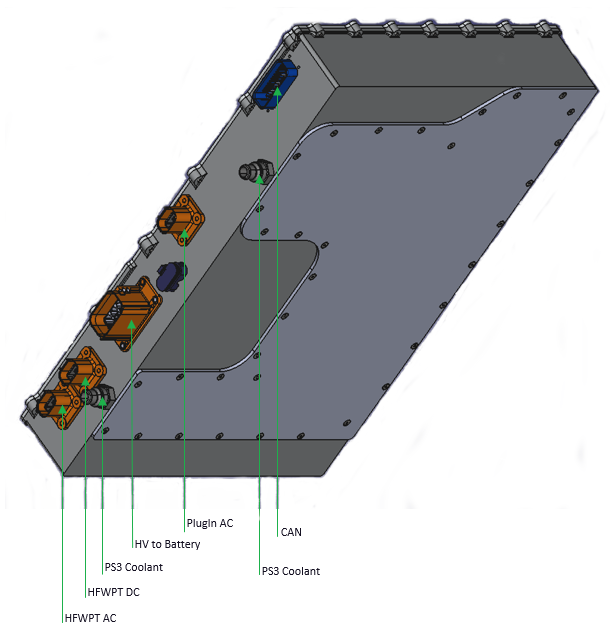

Mitigation of duplicate power conversion pathways, provision of interoperability, and simplification of in-vehicle installation.

Tri-Functional OBC

Inputs: Wireless AC (~85kHz), Plug-In AC (50-60Hz, 61851/J1772), Auxiliary DC. Bidirectional, Modular.

Ease of Installation

Our WPT3 Z2 specification (as per SAE J2954) VA coil does not require active cooling, due to all switching being in the onboard charger.

Thus, in-vehicle integration is simplified by reduction of plumbing and a thin-profile VA coil design.